介紹

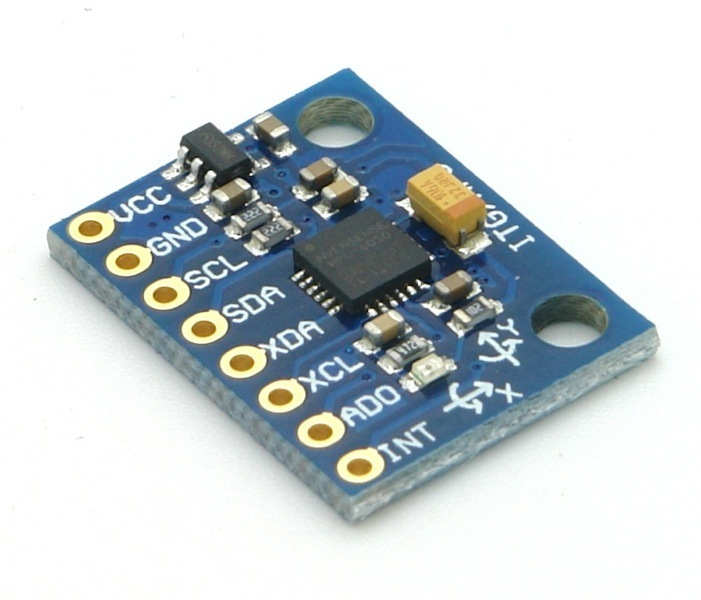

MPU6050模塊

MPU6050 傳感器模塊是一個集成的 6 軸運動跟踪設備。

- 它有一個 3 軸陀螺儀、3 軸加速度計、數字運動處理器和一個溫度傳感器,所有這些都在一個 IC 中。

- 它可以使用其輔助 I2C 總線接受來自其他傳感器的輸入,例如 3 軸磁力計或壓力傳感器。

- 如果外接 3 軸磁力計,可提供完整的 9 軸 Motion Fusion 輸出。

陀螺儀和加速度計沿 X、Y 和 Z 軸的讀數以 2 的補碼形式提供。

溫度讀數以有符號整數形式提供(不是 2 的補碼形式)。

陀螺儀讀數以度/秒 (DPS) 為單位;加速度計讀數以 g 為單位,溫度讀數以攝氏度為單位。

有關 MPU6050 傳感器模塊及其使用方法的更多信息,請參閱傳感器和模塊部分中的主題 MPU6050 傳感器模塊 。

NodeMCU 可以使用 I2C 通信協議與該模塊進行通信。要了解有關 NodeMCU 中 I2C 功能的更多信息,請參閱 NodeMCU I2C with ESPlorer IDE或NodeMCU I2C with Arduino IDE

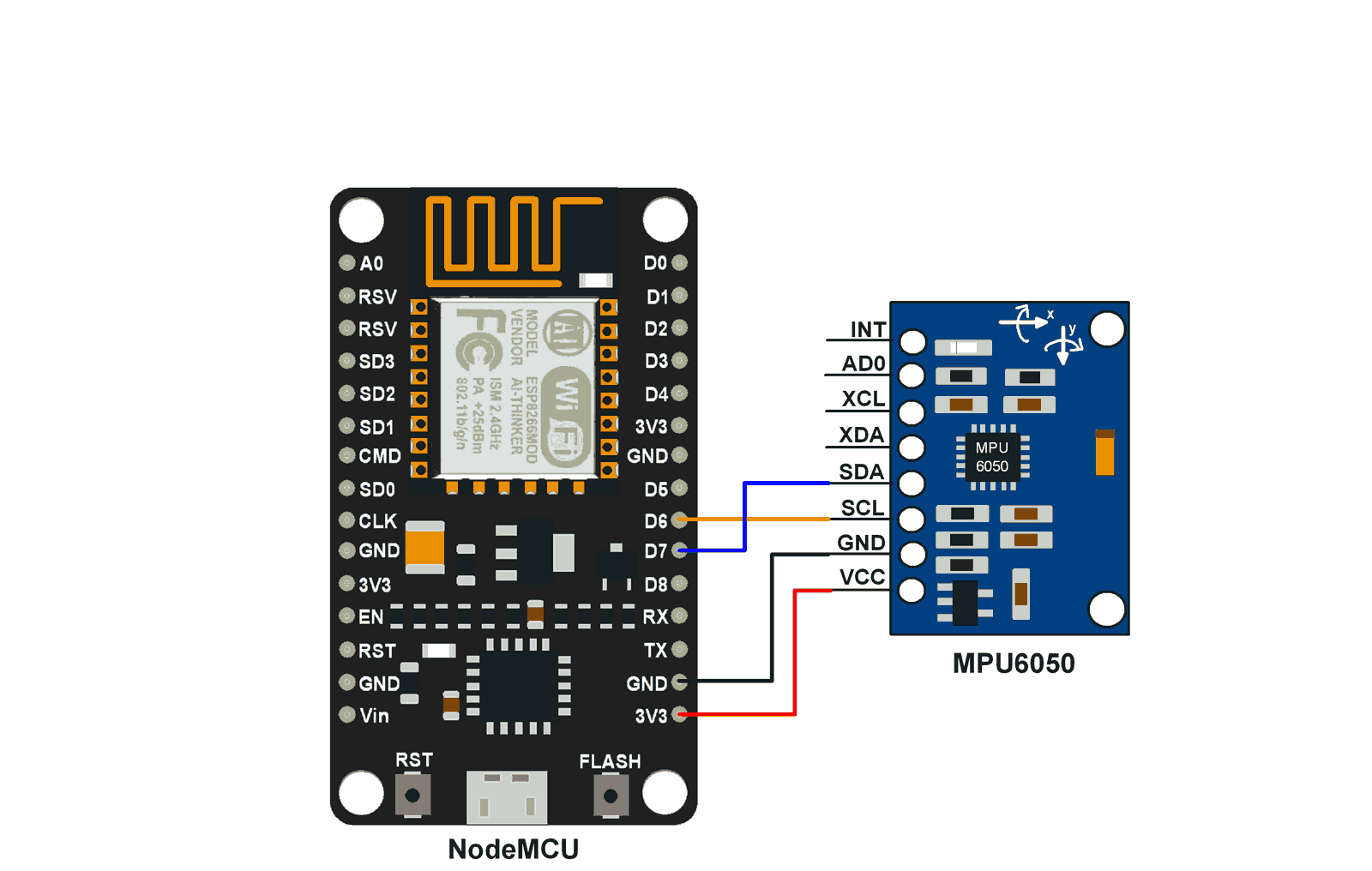

接口圖

NodeMCU 與 MPU6050 的接口

例子

從 MPU6050 模塊讀取加速度計、陀螺儀和溫度參數,並將它們顯示在串行監視器上。

首先,按照上面的接口圖進行連接。

現在讓我們編寫一個程序,從 MPU6050 讀取加速器、陀螺儀和溫度值。

我們可以用 Lua 腳本或 C/C++ 語言為 NodeMCU DevKit 編寫代碼。我們使用 ESPlorer IDE 用 Lua 腳本編寫代碼,使用 Arduino IDE 用 C/C++ 編寫代碼。要了解更多信息,請參閱 使用 ESPlorer IDE 開始使用 NodeMCU(對 NodeMCU 使用 Lua 腳本)和使用 Arduino IDE 開始使用 NodeMCU(對 NodeMCU 使用基於 C/C++ 語言的 Arduino 草圖)。

NodeMCU 的 Lua 腳本

id = 0 -- always 0

scl = 6 -- set pin 6 as scl

sda = 7 -- set pin 7 as sda

MPU6050SlaveAddress = 0x68

AccelScaleFactor = 16384; -- sensitivity scale factor respective to full scale setting provided in datasheet

GyroScaleFactor = 131;

MPU6050_REGISTER_SMPLRT_DIV = 0x19

MPU6050_REGISTER_USER_CTRL = 0x6A

MPU6050_REGISTER_PWR_MGMT_1 = 0x6B

MPU6050_REGISTER_PWR_MGMT_2 = 0x6C

MPU6050_REGISTER_CONFIG = 0x1A

MPU6050_REGISTER_GYRO_CONFIG = 0x1B

MPU6050_REGISTER_ACCEL_CONFIG = 0x1C

MPU6050_REGISTER_FIFO_EN = 0x23

MPU6050_REGISTER_INT_ENABLE = 0x38

MPU6050_REGISTER_ACCEL_XOUT_H = 0x3B

MPU6050_REGISTER_SIGNAL_PATH_RESET = 0x68

function I2C_Write(deviceAddress, regAddress, data)

i2c.start(id) -- send start condition

if (i2c.address(id, deviceAddress, i2c.TRANSMITTER))-- set slave address and transmit direction

then

i2c.write(id, regAddress) -- write address to slave

i2c.write(id, data) -- write data to slave

i2c.stop(id) -- send stop condition

else

print("I2C_Write fails")

end

end

function I2C_Read(deviceAddress, regAddress, SizeOfDataToRead)

response = 0;

i2c.start(id) -- send start condition

if (i2c.address(id, deviceAddress, i2c.TRANSMITTER))-- set slave address and transmit direction

then

i2c.write(id, regAddress) -- write address to slave

i2c.stop(id) -- send stop condition

i2c.start(id) -- send start condition

i2c.address(id, deviceAddress, i2c.RECEIVER)-- set slave address and receive direction

response = i2c.read(id, SizeOfDataToRead) -- read defined length response from slave

i2c.stop(id) -- send stop condition

return response

else

print("I2C_Read fails")

end

return response

end

function unsignTosigned16bit(num) -- convert unsigned 16-bit no. to signed 16-bit no.

if num > 32768 then

num = num - 65536

end

return num

end

function MPU6050_Init() --configure MPU6050

tmr.delay(150000)

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_SMPLRT_DIV, 0x07)

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_PWR_MGMT_1, 0x01)

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_PWR_MGMT_2, 0x00)

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_CONFIG, 0x00)

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_GYRO_CONFIG, 0x00)-- set +/-250 degree/second full scale

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_ACCEL_CONFIG, 0x00)-- set +/- 2g full scale

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_FIFO_EN, 0x00)

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_INT_ENABLE, 0x01)

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_SIGNAL_PATH_RESET, 0x00)

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_USER_CTRL, 0x00)

end

i2c.setup(id, sda, scl, i2c.SLOW) -- initialize i2c

MPU6050_Init()

while true do --read and print accelero, gyro and temperature value

data = I2C_Read(MPU6050SlaveAddress, MPU6050_REGISTER_ACCEL_XOUT_H, 14)

AccelX = unsignTosigned16bit((bit.bor(bit.lshift(string.byte(data, 1), 8), string.byte(data, 2))))

AccelY = unsignTosigned16bit((bit.bor(bit.lshift(string.byte(data, 3), 8), string.byte(data, 4))))

AccelZ = unsignTosigned16bit((bit.bor(bit.lshift(string.byte(data, 5), 8), string.byte(data, 6))))

Temperature = unsignTosigned16bit(bit.bor(bit.lshift(string.byte(data,7), 8), string.byte(data,8)))

GyroX = unsignTosigned16bit((bit.bor(bit.lshift(string.byte(data, 9), 8), string.byte(data, 10))))

GyroY = unsignTosigned16bit((bit.bor(bit.lshift(string.byte(data, 11), 8), string.byte(data, 12))))

GyroZ = unsignTosigned16bit((bit.bor(bit.lshift(string.byte(data, 13), 8), string.byte(data, 14))))

AccelX = AccelX/AccelScaleFactor -- divide each with their sensitivity scale factor

AccelY = AccelY/AccelScaleFactor

AccelZ = AccelZ/AccelScaleFactor

Temperature = Temperature/340+36.53-- temperature formula

GyroX = GyroX/GyroScaleFactor

GyroY = GyroY/GyroScaleFactor

GyroZ = GyroZ/GyroScaleFactor

print(string.format("Ax:%.3g Ay:%.3g Az:%.3g T:%.3g Gx:%.3g Gy:%.3g Gz:%.3g",

AccelX, AccelY, AccelZ, Temperature, GyroX, GyroY, GyroZ))

tmr.delay(100000) -- 100ms timer delay

end

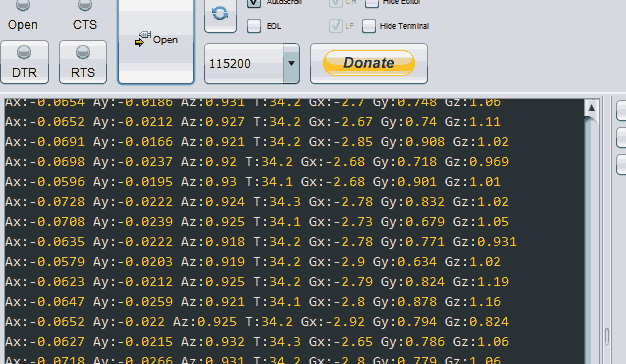

ESPlorer 串行輸出窗口

上述 Lua 腳本的 ESPlorer IDE 串口窗口的輸出窗口如下圖所示

Ax = 加速度計 x 軸數據,單位為 g

Ay = 加速度計 y 軸數據,單位為 g

Az = 加速度計 z 軸數據,單位為 g

T = 溫度/攝氏度

Gx = 陀螺儀 x 軸數據,以度/秒為單位

Gy = 以度/秒為單位的陀螺 y 軸數據

Gz = 陀螺儀 z 軸數據,以度/秒為單位

用於 NodeMCU 的 Arduino 草圖

#include <Wire.h>

// MPU6050 Slave Device Address

const uint8_t MPU6050SlaveAddress = 0x68;

// Select SDA and SCL pins for I2C communication

const uint8_t scl = D6;

const uint8_t sda = D7;

// sensitivity scale factor respective to full scale setting provided in datasheet

const uint16_t AccelScaleFactor = 16384;

const uint16_t GyroScaleFactor = 131;

// MPU6050 few configuration register addresses

const uint8_t MPU6050_REGISTER_SMPLRT_DIV = 0x19;

const uint8_t MPU6050_REGISTER_USER_CTRL = 0x6A;

const uint8_t MPU6050_REGISTER_PWR_MGMT_1 = 0x6B;

const uint8_t MPU6050_REGISTER_PWR_MGMT_2 = 0x6C;

const uint8_t MPU6050_REGISTER_CONFIG = 0x1A;

const uint8_t MPU6050_REGISTER_GYRO_CONFIG = 0x1B;

const uint8_t MPU6050_REGISTER_ACCEL_CONFIG = 0x1C;

const uint8_t MPU6050_REGISTER_FIFO_EN = 0x23;

const uint8_t MPU6050_REGISTER_INT_ENABLE = 0x38;

const uint8_t MPU6050_REGISTER_ACCEL_XOUT_H = 0x3B;

const uint8_t MPU6050_REGISTER_SIGNAL_PATH_RESET = 0x68;

int16_t AccelX, AccelY, AccelZ, Temperature, GyroX, GyroY, GyroZ;

void setup() {

Serial.begin(9600);

Wire.begin(sda, scl);

MPU6050_Init();

}

void loop() {

double Ax, Ay, Az, T, Gx, Gy, Gz;

Read_RawValue(MPU6050SlaveAddress, MPU6050_REGISTER_ACCEL_XOUT_H);

//divide each with their sensitivity scale factor

Ax = (double)AccelX/AccelScaleFactor;

Ay = (double)AccelY/AccelScaleFactor;

Az = (double)AccelZ/AccelScaleFactor;

T = (double)Temperature/340+36.53; //temperature formula

Gx = (double)GyroX/GyroScaleFactor;

Gy = (double)GyroY/GyroScaleFactor;

Gz = (double)GyroZ/GyroScaleFactor;

Serial.print("Ax: "); Serial.print(Ax);

Serial.print(" Ay: "); Serial.print(Ay);

Serial.print(" Az: "); Serial.print(Az);

Serial.print(" T: "); Serial.print(T);

Serial.print(" Gx: "); Serial.print(Gx);

Serial.print(" Gy: "); Serial.print(Gy);

Serial.print(" Gz: "); Serial.println(Gz);

delay(100);

}

void I2C_Write(uint8_t deviceAddress, uint8_t regAddress, uint8_t data){

Wire.beginTransmission(deviceAddress);

Wire.write(regAddress);

Wire.write(data);

Wire.endTransmission();

}

// read all 14 register

void Read_RawValue(uint8_t deviceAddress, uint8_t regAddress){

Wire.beginTransmission(deviceAddress);

Wire.write(regAddress);

Wire.endTransmission();

Wire.requestFrom(deviceAddress, (uint8_t)14);

AccelX = (((int16_t)Wire.read()<<8) | Wire.read());

AccelY = (((int16_t)Wire.read()<<8) | Wire.read());

AccelZ = (((int16_t)Wire.read()<<8) | Wire.read());

Temperature = (((int16_t)Wire.read()<<8) | Wire.read());

GyroX = (((int16_t)Wire.read()<<8) | Wire.read());

GyroY = (((int16_t)Wire.read()<<8) | Wire.read());

GyroZ = (((int16_t)Wire.read()<<8) | Wire.read());

}

//configure MPU6050

void MPU6050_Init(){

delay(150);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_SMPLRT_DIV, 0x07);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_PWR_MGMT_1, 0x01);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_PWR_MGMT_2, 0x00);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_CONFIG, 0x00);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_GYRO_CONFIG, 0x00);//set +/-250 degree/second full scale

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_ACCEL_CONFIG, 0x00);// set +/- 2g full scale

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_FIFO_EN, 0x00);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_INT_ENABLE, 0x01);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_SIGNAL_PATH_RESET, 0x00);

I2C_Write(MPU6050SlaveAddress, MPU6050_REGISTER_USER_CTRL, 0x00);

}

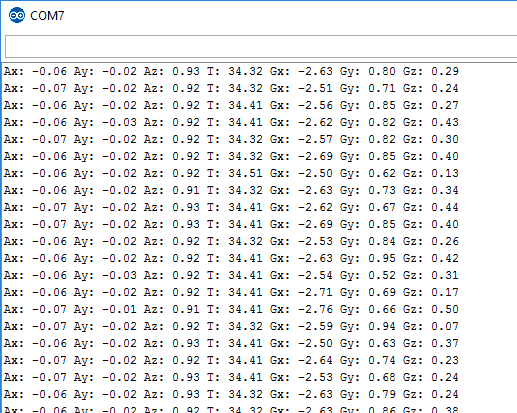

Arduino 串行輸出窗口

上述 Arduino 草圖的 Arduino IDE 串行窗口的輸出窗口如下所示

Ax = 加速度計 x 軸數據,單位為 g

Ay = 加速度計 y 軸數據,單位為 g

Az = 加速度計 z 軸數據,單位為 g

T = 溫度/攝氏度

Gx = 陀螺儀 x 軸數據,以度/秒為單位

Gy = 以度/秒為單位的陀螺 y 軸數據

Gz = 陀螺儀 z 軸數據,以度/秒為單位

資料來源:https://www.electronicwings.com/nodemcu/mpu6050-interfacing-with-nodemcu

沒有留言:

張貼留言